The origins of the factory’s vast experience and traditions date back to over 130 years ago.

We continue to enrich the history of the enterprise with new technological achievements, to achieve outstanding results worthy of our heritage.

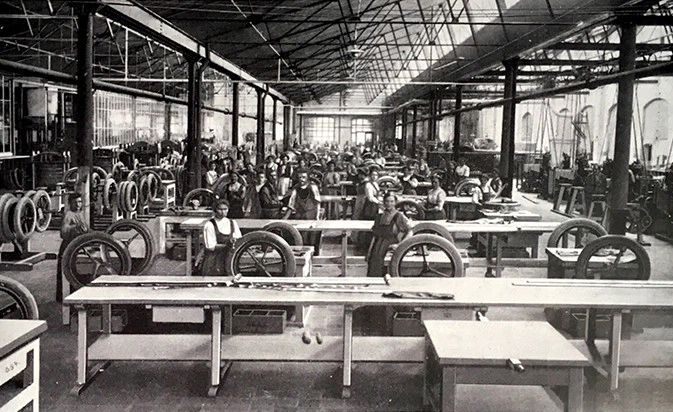

1888

The enterprise was originally based on the former joint Russian and French partnership “Provodnik”, a manufacturing plant where the production of technical and surgical rubber products, linoleum and hard rubber items began. At the time, “Provodnik” used to be the world’s 4th largest producer of rubber products and the 2nd largest car tyre producer.

1946

The former territory of the “Provodnik” factory was allocated for the construction of electrical equipment for electric commuter trains.

Production of the first batch of DTI-60 tram engine tram engine coils and passenger car power supply systems with RD-2 generators.

During this period, the factory was supplemented with a mechanical repair shop, a tool shop, a winding and insulation shop, an anchor shop and a small parts shop.

1949

Organisation of the production of DK-103 electric train engines.

Launch of the SR electric train equipment line.

Production of generators for RD-2D passenger cars and DSchR-8A railway car lighting switchboards.

1950

RER was the first factory in the Soviet Union to set up the production of EAYa-2 washing machines.

Commencement of serial production of electrical equipment for ER-1 ten car electric trains.

Commissioning of new plastic-based commutators for PN-10 engines.

1960

Introduction of a series of innovative products for the first time in the Soviet Union: electric equipment for ER9 and ER22 electric trains, washing machines, wear-resistant PME-200 magnetic starters.

Commencement of production of electric engines and devices for electric forklifts and CMVC-61 power cars.

Development of 10 new types of electric train machinery sets, several kings of electric equipment for passenger rail cars.

1970

The first trial runs of electric equipment for ER-200, a 3 kW direct-current electric train capable of accelerating to 200 km/h.

Development of a new semi-automatic washing machine, the “Riga-20”.

Production of prototype electric equipment for light electric vehicles and electric trucks with power recuperation on braking to the accumulator battery.

Design of electric equipment for blast-proof electric forklifts.

1980

Production of 20 Latvian electric motor vehicles under the brand of RAF, with REZ electrics.Design of electric equipment for electric vehicles, electric carts, clamp trucks, tractor trucks and forklifts with carrying capacity of 0.63 to 45 tons.Design of electric equipment with pulse start and recuperation for ER29 and ER30 alternate- and direct-current trains.Design of electric equipment with braking capability and recuperation for ER2R/ED2T 3 kW direct-current trains.

1990

Production of electric equipment for ED2M, ED4M direct-current trains and ED9M alternate-current trains.

Production of wind generator plants with 1 to 3 kW generators.

Development of electric equipment sets for locomotive passenger rail cars with 32 kW 2GV.13U1 inductor generators.

Development of electric equipment sets for passenger rail cars with centralised power supply running at speeds of up to 200 km/h.

Production of electric equipment for ET2M direct-current trains with electric braking.

Development of electric engine switching systems for railway trains yielding power economy of up to 20%.

2000

Restructuring of the factory into a joint stock company.

Production of the 5DT-117 MU direct-current subway train traction engine..

Development of an electric equipment unit for the EPL2T direct-current electric train with regenerative-rheostatic braking electrodynamics.

Development of advanced technologies – asynchronous traction drives for suburban electric trains.

2010

Production of the DTA-170 asynchronous subway train traction engine.

Production of an electric equipment set for the EP2D direct-current train.

Production of an electric equipment set for the EG2Tv direct-current train with an asynchronous drive for MCD-1, -2.

Production of electric equipment sets for upgrading 81-717/714 subway trains.

Development of an asynchronous drive unit for the BelAZ-90 dump truck.

Development of electric equipment sets for escort railcars and locomotive postal-baggage cars with a 12 kW.

2020

Today, RER pursues further industrial development with a focus on latest trends in the electrical engineering industry.

Fascinated by new challenges, we are willing to develop technologies to improve the operation of transport and power infrastructure.