At RER – Riga Electrical Machinery Factory, the Mechanical and Preparation Shop is divided into two main sections: production preparation and machining.

When raw metal, such as sheets, profiles, strips, pipes, round bars, or channels, enters production, it first goes to the production preparation section.

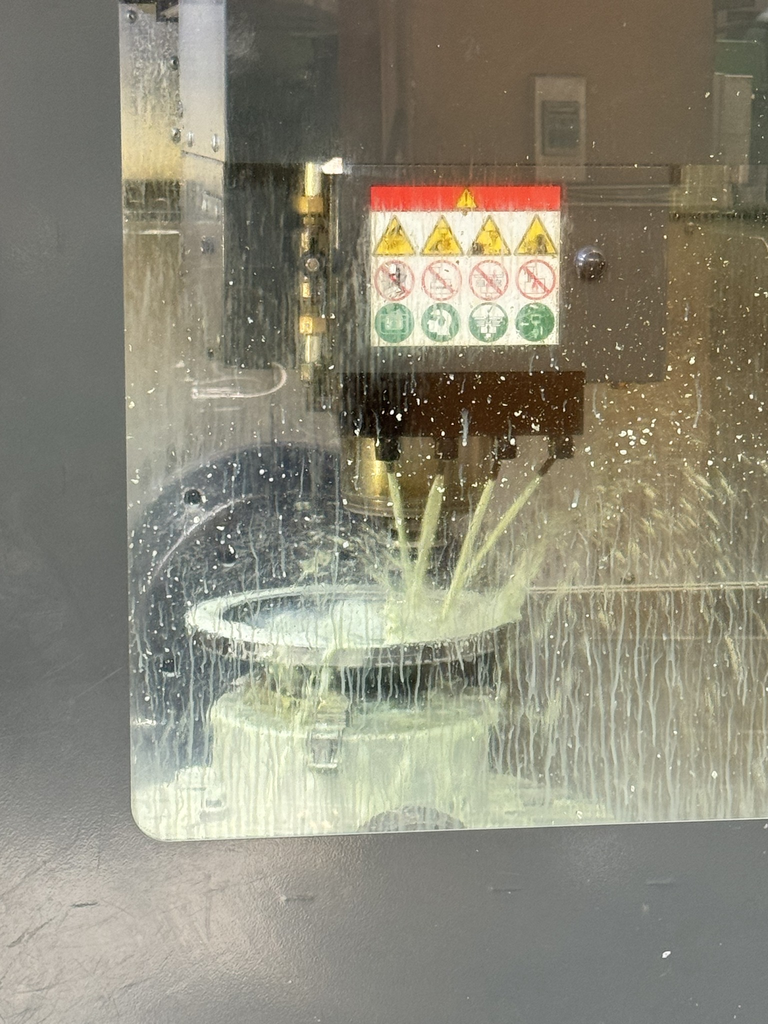

There, it is cut or shaped using guillotine shears, press brakes, band saws, and hydroabrasive cutting machines.

The processed material then proceeds to the machining section , where more complex parts are manufactured through processes such as stamping, turning, milling, drilling, and tapping.

Finally, the finished components are sent to assembly units for integration into RER’s final products.

Behind every finished product is a clear process and precision at every stage.